Attach Your Blank Tags with These 3 Methods

- USQuickBlogs

- 30 Oct, 2019

You ordered your blank tags, marked them with your custom information, and now it’s time to use them. Metal nameplates must be attached to equipment, machinery, tools, or anything else you need marked. Otherwise they don’t really serve a purpose.

Mounting Holes

The “standard” attachment method for metal identification is direct mounting via holes. When shopping for blank tags, you are presented with options for various hole configurations. This includes one, two, and four hole varieties.

These holes are cut or punched out of the blank metal when the nameplates are produced. This eliminates any additional drilling or modification by the end user.

Holes are cut directly into the blank tags during production, meaning the end user doesn’t have to worry about drilling or punching their own.

Larger tags might be best suited for two or four holes, as they feature a larger surface area. Smaller sizes can get away with using one or two holes. If your applications calls for a very specific hole pattern, the tags will have to be custom made to accommodate.

Screws/Bolts

Mounting nameplates is a very simple process that anyone can handle. Simply slide screws or bolts into the already cut holes, and fasten to the equipment, tool, or other asset that is being marked. It can’t get much simpler than that.

If this is the attachment method you elect to use, don’t forget that it does require additional hardware. Screws and bolts do not come with the identification tags, and are typically not something tag manufacturers sell. A quick stop at the hardware store can save you a bit of money and time.

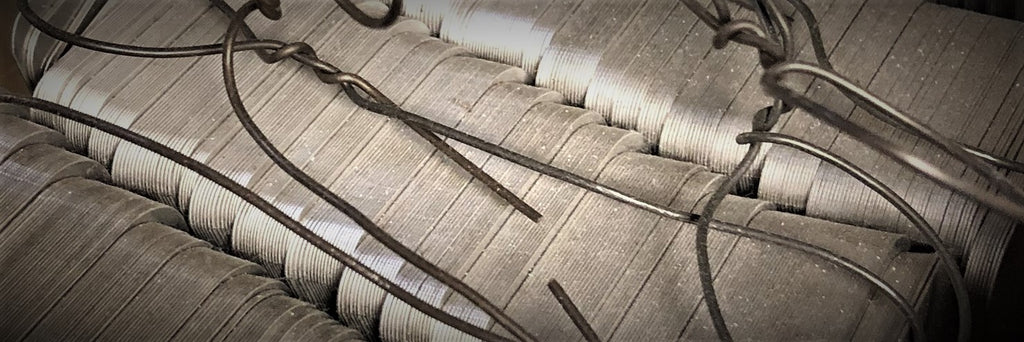

Wires/Chains

What about marking pipes or valves? What about my machine which doesn’t have a flat surface to mount screws into?

Where there’s a problem, there is a solution. Metal identification nameplates are not limited to attachment on just items with flat surfaces. Holes are also not limited to using screws or bolts. A basic wire or chain can slip through the hole and wrap around the item, providing a secure fit.

This is commonly used for pipes, cables, valves, and other non-flat identification applications.

Again, additional hardware is needed for this, as wires or chains will not typically come with your blank tags either. Wire mounting opens up many new possibilities for marking equipment, tools, and machines in all shapes and sizes.

Cable Ties

Is there any way I can mount blank tags without using additional hardware (screws/wires)?

Imagine being able to mark information on your tags, and then in one simple motion attach them to a rounded surface without any additional equipment or hardware. It’s not just a dream; metal cable ties are a seamless method for marking cylindrical components.

These cable tags feature an elongated end, which wraps around the object and slides through a slot at the base of the tag. The long end or “tail” then folds over itself, providing an adjustable and secure fit every time.

Cable ties are relied upon for marking cables, wires, valves, pipes, and more.

While these tags are not necessarily the most durable due to their lack of thickness (they must be thin to be flexible) they make up for it in convenience and practicality.

Welding

If permanent attachment is your goal for your identification, the other option is to actually weld your tags to your equipment.

This removes the requirement for additional hardware, and eliminates the risk of your hardware failing or your tag falling off.

Depending on your welding expertise or the type of equipment you use, there may be restrictions on which material to use. (For example, 316 stainless steel) In addition, welding obviously is not right for every application, as certain machinery or tools may be damaged if welded.

Wrap-Up

The main point to consider when selecting a tag attachment method is which best fits your specific application. Nobody knows your environment and application better than your organization.

Making sure your tags and nameplates will be functional in the field is crucial. If they are going to fall off the machines, or be difficult to attach, they can cause more problems than having no identification at all.

Take your time and consider all the options before deciding on the right attachment method for your tags.