Best Processes for Marking Blank Tags

- USQuickBlogs

- 18 Oct, 2019

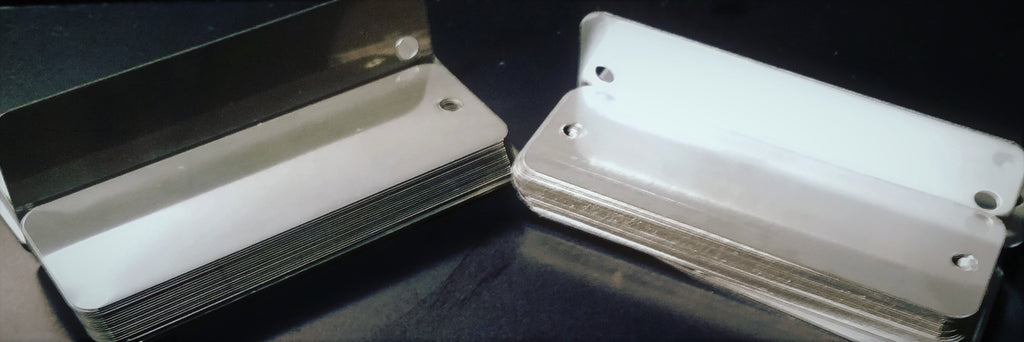

Industries of all types utilize blank metal tags for a wide variety of applications. These blanks are marked with relevant information for a specific use.

Marking blank metal tags is completed in a variety of ways, including automated machines or marking by hand.

Here we will discuss some of the more professional part marking methods and the benefits of each.

Automated Machines

Embossing Machines

Embossing machines are a great tool for marking high volumes of tags in-house. While the machines can be more costly than other solutions, the benefits can pay off for high volume projects. This is especially true with variable information.

These machines are typically auto-feed machines, meaning there is little physical interaction needed from workers. However this also means the tags must be flat, to work properly with the feed system and prevent jamming or damage to the blanks when they are embossed.

Training is relatively easy, only basic knowledge of Microsoft Excel is necessary, as that is the typical input program for these machines.

Dot Peen Machines

Dot Peen marking has become very popular as it allows computer programmed information (variable data) to be marked on the tags without having to stamp the characters by hand. This can save a large amount of time, while making the text look more professional and uniform than individual hand stamps.

Dot peen machines also have the ability to mark data matrix barcodes, allowing the tags to be scanned with virtually any smart phone. This allows you to store an incredible about of data in a small area, and can be customized with a wide array of software programs.

Other Methods

Stamping

Stamping has a variety of types, from individual hand stamps, to multiple text holders, and rotating wheels.

The best solution really comes down to your specific usage. Hand stamps may be best for low volume projects, especially if small amounts of data are being put on each tag.

If you are stamping constant information a holder may be best. This allows you to typeset a specific amount of information and mark all of the text with one hit.

If the information is going to change, and you still want the professional look, a stamping wheel may be best as this will help keep the text uniformly in-line.

Laser Marking

Laser marking is becoming more and more prevalent as companies are buying versatile lasers which are capable of multiple functions.

This process creates a black on silver contrast, and also allows for barcodes and variable data. However, you will want to make sure you get flat tags to ensure equal markings.

In addition, the laser process is best used for indoor, low abuse environments as most laser marking is very light and cannot handle much wear before it becomes illegible.

Wrap-Up

There are a wide range of ways to mark your blank metal tags in house. The best solution for “you” is based your unique situation. Some factors to consider: the volume of tags you are going to be marking per day, durability requirements, and aesthetic preferences.