Mark Blank Tags In-House: Embossing Machines

- USQuickBlogs

- 11 Oct, 2019

Marking tags and nameplates by hand can be incredibly tedious and time consuming. Many organizations utilize embossing machines to mark their own blank tags in-house.

They are sometimes referred to as variable data embossing machines as they can embed unique information on each nameplate.

While the majority of custom marking machines emboss the tags, there are machines which indent the information rather than raise it.

These machines are simple to use, and just require basic knowledge of Excel for inputting data.

In addition, manufacturers of custom tags often use them for small scale production runs.

Why Not Just Order Custom Marked Tags?

Why would you invest in an embossing machine when you can just order tags with information already marked on them?

It primarily depends on how you want to use tags, and the quantity you will need.

If you are only going to use a couple tags per week, buying marked tags from a custom manufacturer can be very expensive as volume is key. Whereas, if you need several hundred per week it might make more sense just to have the tags pre-marked.

What if you don’t know the information you need on the tags in advance?

Ordering custom nameplates means providing the information well in advance. In many instances, your organization won’t know what is going on the tag until it is time to label the item.

Embossing machines allow for on the spot marking as you need tags. For example, you purchase a new set of tools for a new hire and want to mark them. You don’t want to spend several weeks (and more money) ordering custom made tags. It makes more sense to mark the few tags in-house using the blanks you have on hand.

Limitations

Using an embossing machine does come with its own set of drawbacks. Machines have size restrictions for tags. Most auto-feed style devices are only compatible with rectangle shaped blanks.

In addition, an embossing machine can only mark characters with pre-determined sizes and fonts.

This also means you can’t mark any type of custom imagining, barcodes, or logos. Special character options are also limited based on the specific machine you use.

Special information types are best handled by a custom manufacturer, but will be at a premium compared to the blank tags.

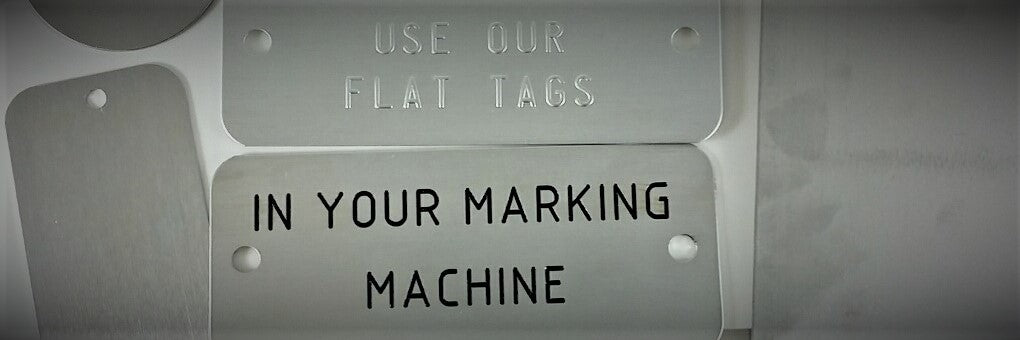

Flat Tags

In addition, embossing machines typically require flat tags. If the blanks you run into the machine are not flat, they can jam the machine, damage the material, or otherwise not mark properly.

If you plan to use blank tags for an embossing machine application, you should communicate this to your supplier as they can provide the optimal solution.

Every machine is different, so refer to the specific guidelines provided by the manufacturer.

Materials

The most commonly used materials for embossing machines are aluminum and stainless steel. These materials are preferable due to their durability and versatility across many industrial type applications.

There are also machines which specialize in plastic, paper, or other non-metal materials.

Industries

There are a wide range of industries which rely on marking their tags in-house with an embossing machine. From embossing before heading out to a job site, or marking tags for something in the plant, there are endless applications for embossing machine tags.

- Energy

- Oil & Gas

- Aerospace

- Construction

- And Many More!

Wrap Up

If your organization spends a considerable amount of time marking tags by hand, utilizing an embossing machine makes a lot of sense. Not only does automated marking save you time, but also offers versatility. Marking tags as needed also allows for custom tagging without the wait for a manufacturer to produce the designs. For many organizations, embossing machines are a worthwhile investment.